AI‑Driven Procurement Cost Reduction Workflow for Smarter Supply Chain Management

Use AI‑driven Supply Chain Price Optimization to automate grocery procurement, monitor live supplier prices, and achieve smarter sourcing decisions that cut costs and boost profit efficiency.

Global supply networks and complex pricing models have made managing costs and profit margins more challenging than ever. Rising material prices, fluctuating demand, and competitive pressure are forcing organizations to focus on cost reduction and cost optimization across the entire value chain. Forward‑thinking companies are now integrating AI in procurement with supply chain analytics and price optimization strategies to build resilience, improve cost control, and secure sustainable profitability.

The Supply Chain Price Optimization (Grocery) — powered by BrowserAct and Make.com — provides an automated, AI‑driven system for continuous procurement and sourcing costs Optimization.

Click to watch our tutorial video below and see the scraper in action!👇

What is Procurement Cost?

Procurement cost refers to the total expense a company incurs to acquire goods or services needed for its operations. It goes far beyond just the sticker price of raw materials or purchased items. According to Invensis, true procurement costs encompass all direct, indirect, and lifecycle expenditures related to sourcing, negotiating, purchasing, receiving, and managing materials or services.

These costs can be divided into several categories:

- Direct Costs – The visible costs of buying goods or services, such as raw materials, packaging, or finished products.

- Indirect Costs – Expenses tied to supporting procurement activities like transportation, warehousing, inspection, and taxes.

- Process Costs – Administrative and operational overhead from purchase order creation, approvals, payments, and compliance tracking.

- Lifecycle Costs (TCO) – The total cost of ownership, which includes maintenance, support, and end‑of‑life disposal.

In other words, procurement cost reflects the true cost of acquiring and managing resources throughout their full life cycle. Businesses that fail to account for hidden or long‑term expenses often underestimate their total procurement spending — and miss significant opportunities for cost optimization.

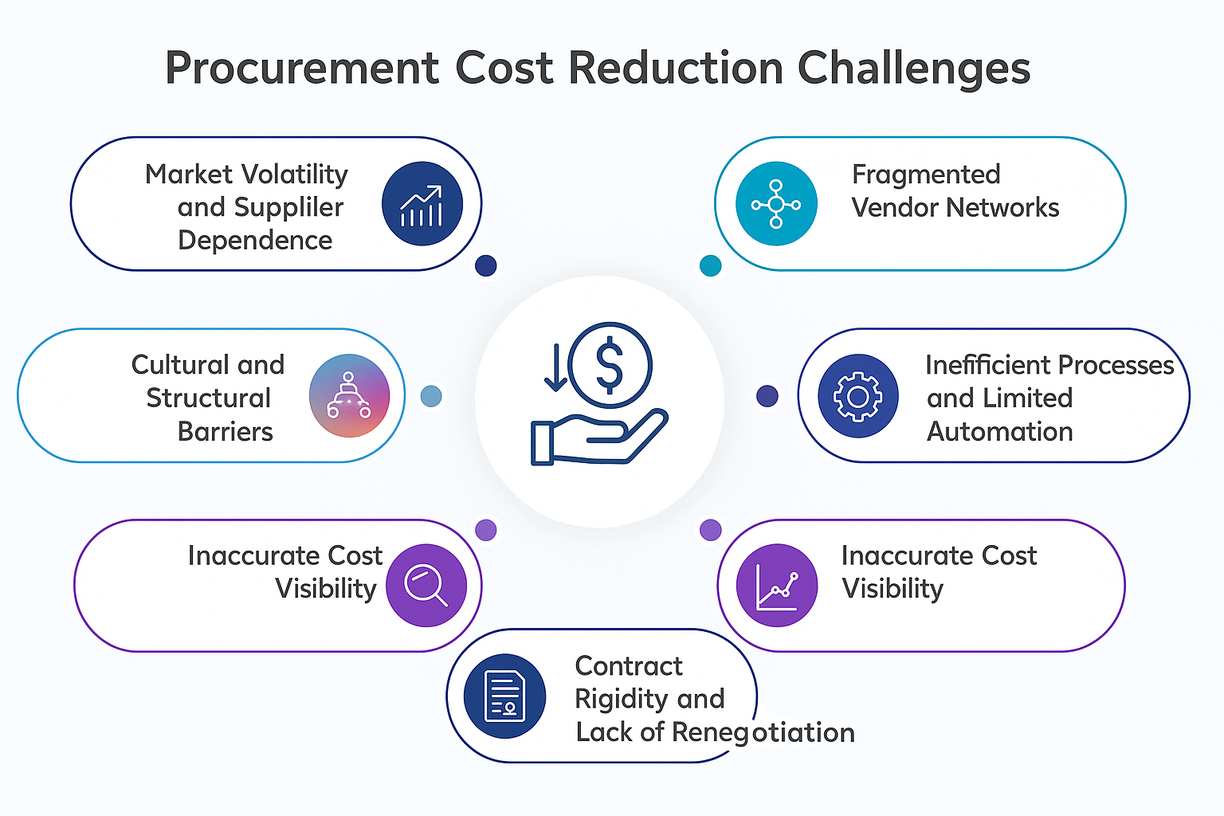

Challenges In Procurement Cost Savings and How to Measure Them

- Market Volatility and Supplier Dependence

Raw material and logistics prices fluctuate rapidly, often driven by global disruptions or regional supply constraints. This volatility erodes planned savings and limits long‑term visibility into cost structures. - Fragmented Vendor Networks

Working with too many suppliers leads to inconsistent pricing, differing contractual terms, and excess administrative overhead — all of which diminish negotiating power and complicate spend tracking. - Inefficient Processes and Limited Automation

Many organizations still rely on manual approvals, emails, and spreadsheets. These outdated workflows increase procurement cycle times, create data errors, and make cost validation difficult. - Incomplete Cost Visibility

Companies often focus only on purchase prices while neglecting indirect or lifecycle costs such as storage, transportation, warranty, and disposal. This narrow view underestimates the total cost of ownership (TCO). - Inaccurate Forecasting and Reactive Planning

Poor demand forecasting can result in overstocking or stockouts — both of which inflate procurement and inventory carrying costs. The absence of real‑time analytics leaves teams reacting instead of anticipating. - Contract Rigidity and Lack of Renegotiation

Long‑term fixed contracts that are not reviewed periodically prevent organizations from capturing savings available through market changes or supplier performance improvements. - Cultural and Structural Barriers

Cost optimization requires collaboration between procurement, finance, and operations. In many companies, siloed functions and weak data sharing limit transparency and accountability.

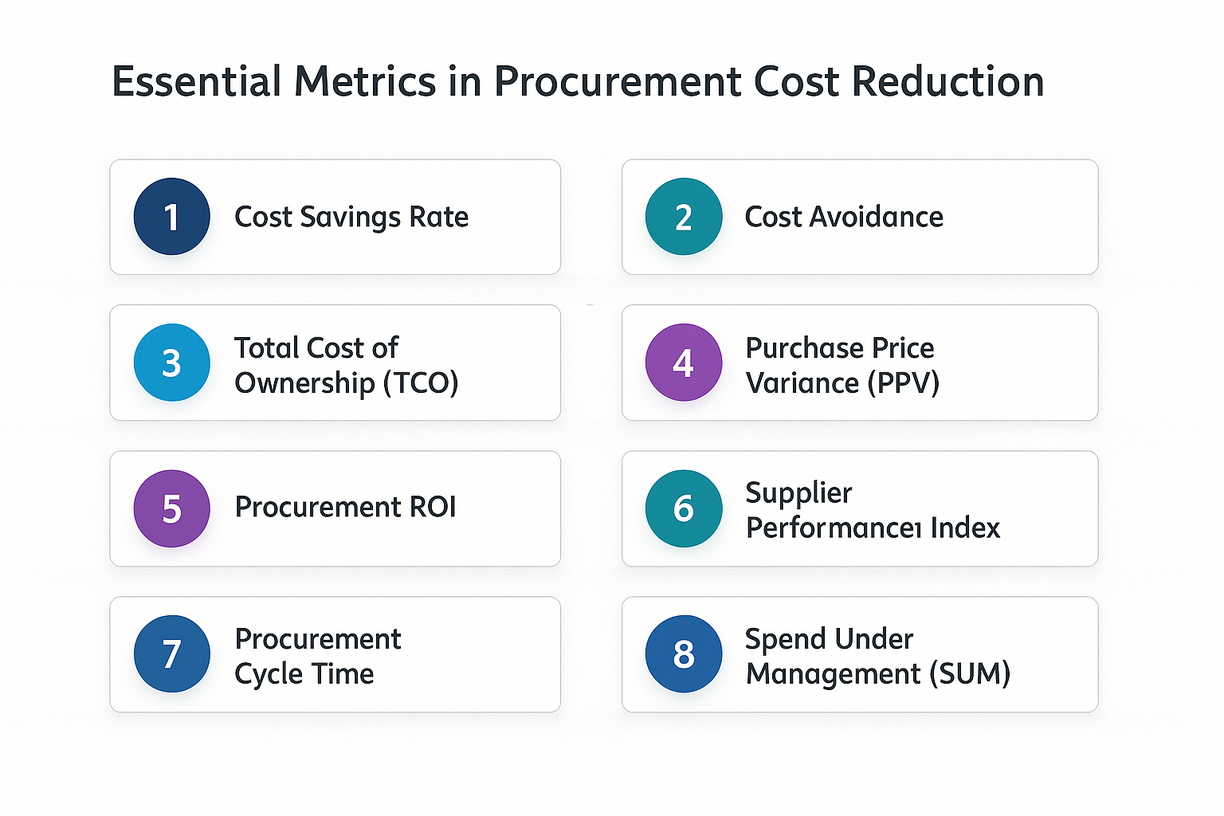

To translate these challenges into actionable insights, procurement leaders must establish clear cost analysis metrics. These indicators help organizations quantify efficiency, uncover bottlenecks, and verify whether cost‑saving initiatives are truly delivering value.

Metric | What It Measures | Why It Matters |

Cost Savings Rate | The percentage reduction achieved compared to baseline procurement cost. | Demonstrates the financial effectiveness of optimization efforts. |

Cost Avoidance | The value of costs prevented through renegotiation, process improvement, or risk mitigation. | Reveals hidden benefits that protect profit margins over time. |

Total Cost of Ownership (TCO) | Full lifecycle cost, including maintenance, storage, transport, and disposal. | Encourages long‑term strategic sourcing rather than short‑term price cuts. |

Purchase Price Variance (PPV) | The difference between standard and actual buying prices. | Identifies inefficiencies or missed negotiation opportunities. |

Procurement ROI | Net financial benefits versus investment in procurement processes and technology. | Validates the business impact of digital transformation in procurement. |

Supplier Performance Index | Assessment of supplier reliability, cost competitiveness, and service quality. | Links supplier behavior directly with organizational cost performance. |

Procurement Cycle Time | Time from requisition to purchase order completion. | Measures process efficiency and the value of automation. |

Spend Under Management (SUM) | Percentage of total spend handled through structured procurement systems. | Indicates the degree of governance, transparency, and cost control. |

Understanding the challenges and tracking these metrics in isolation is only the first step. The next evolution lies in automating cost analysis and supplier benchmarking through AI‑enabled systems — tools capable of detecting anomalies, predicting market changes, and calculating optimal procurement decisions in real time. By integrating these principles into our Supply Chain Price Optimization (Grocery) Template, businesses can continuously measure procurement performance, uncover hidden inefficiencies, and achieve tangible cost reduction and control — not once, but continuously.

Key Functions of Supply Chain Price Optimization (Grocery)

1️⃣ BrowserAct Data Extraction

- Automatically visits supplier or retailer websites.

- Searches based on product names and quantity/count.

- Extracts product title, seller, price, quantity, and URL.

- Structures them into clean, standardized JSON output for analysis.

This step replicates the “real‑world” data of diverse sellers and becomes the cost baseline for automation.

2️⃣ Data Storage & Integration

- Imports JSON data into Make’s workflow modules.

- Saves to Google Sheets or internal database for tracking price fluctuations.

- Enables long‑term supply chain analytics and historical trend analysis.

3️⃣ AI‑Based Price and Quantity Optimization

- Uses AI pricing modeling to compute price‑per‑quantity (PPQ) ratios.

- Automatically selects the two cheapest and most efficient suppliers.

- Facilitates precision purchasing and dynamic pricing adjustments.

4️⃣ Automated Comparison & Reporting

- AI response parsed, compared, and validated.

- Automatically sends optimized supplier data and pricing results to a Telegram Bot or notification channel.

- Ensures decision‑makers receive real‑time alerts on best pricing opportunities.

Value Realization for the Users

Performance Area | Key Metrics | Achieved Impact |

Cycle Time Reduction | Lead time from requisition to purchase order | ↓ 65% |

Error Minimization | Mispricing, duplicate invoicing, and order discrepancies | ↓ 80% |

Annualized Cost Savings | Category‑level procurement costs | ↓ 12–20% |

ROI (12‑Month) | Net benefit vs. implementation cost | 3.4× financial return |

Decision Speed | Cross‑department procurement approvals | ↑ 50% |

Supplier Visibility | Data coverage and performance tracking | ↑ 85% |

Use Cases — Real Ways to Apply It

Persona | Objectives | How the Template Helps |

🛒 Procurement Managers | Need to source grocery goods at the most competitive cost | Automates supplier price comparisons, saves 70–80% of manual research time |

📈 Supply Chain Analysts / Data Teams | Want accurate, structured data to monitor cost fluctuations & supplier behavior | Provides continuous price/quantity insights for supply chain analytics dashboards |

🧠 Pricing Strategists & Category Leads | Aim to adapt retail or wholesale pricing dynamically | Leverage AI models from Make.com to drive AI pricing and dynamic pricing schemes |

🧰 Automation / No‑Code Professionals | Build repeatable workflows for multi‑channel price tracking | Combine BrowserAct + Make to create low‑maintenance, scalable automation ecosystems |

Competitive Supplier Benchmarking & Cost Simulation

The Supply Chain Price Optimization (Grocery) template automates supplier comparison. It uses BrowserAct to extract live product data—titles, weights, prices, and URLs—from online stores and processes it through Make.com, where AI calculates each supplier’s Price‑Per‑Quantity (PPQ). The system instantly identifies the two most cost‑efficient suppliers, giving procurement teams clear visibility into market prices for faster, smarter, and more profitable decisions.

Dynamic Price Tracking Across Retail and Wholesale Channels

This scenario keeps pricing accurate across all channels. Using Make.com’s AI automation, it continuously tracks supplier data from BrowserAct, detects real‑time cost changes, and updates prices in your ERP or retail system automatically. The result is true dynamic pricing that protects margins and keeps prices aligned with the market.

Centralized Supply Chain Analytics & Cost Intelligence

The template turns fragmented procurement data into actionable analytics. Structured outputs allow teams to track price changes, supplier performance, and buying trends. Connected with Make.com dashboards, businesses gain predictive insights for cost forecasting and smarter vendor management.

Automated Price Optimization & AI‑Driven Decision Alerts

AI automatically selects the best suppliers and sends alerts via Telegram Bot or other channels. Each alert includes product details, pricing, and links, enabling instant action. This AI‑based workflow speeds up sourcing decisions and ensures procurement stays aligned with market conditions.

Integration with Dynamic Pricing and Retail Strategy Systems

This scenario connects procurement with retail strategy. Optimal supplier data and PPQ results integrate directly into pricing engines or ERP systems, updating product prices automatically when supplier costs change. It delivers continuous, AI‑driven dynamic pricing that protects margins and improves efficiency.

Real‑Time Collaboration and Supply Chain Synchronization

The template enhances teamwork through real‑time data sharing. Pricing updates and insights are sent via Telegram Bots or dashboards, keeping procurement, finance, and analytics teams aligned. This creates a transparent, agile, and fully synchronized supply chain optimization environment.

Smarter sourcing starts here. With AI and automation at its core, our workflow empowers every procurement team to save time, reduce costs, and make data‑driven decisions that protect profit margins.

Relative Resources

Real‑Time eBay Price Tracker: Make × BrowserAct Automation for Smarter Selling

How Finance Automation Enhances Accuracy, Efficiency, and Strategic Foresight

Real Estate Lead Automation in 2025: How Make × BrowserAct Helps Agents Work Smarter

2025 Ultimate Guide to AI Role‑Play Chatbots

Latest Resources

Moltbook: Where 150K AI Agents Talk Behind Our Backs

How to Bypass CAPTCHA in 2026: Complete Guide & Solutions

Moltbot (Clawdbot) Security Guide for Self-Hosted AI Setup